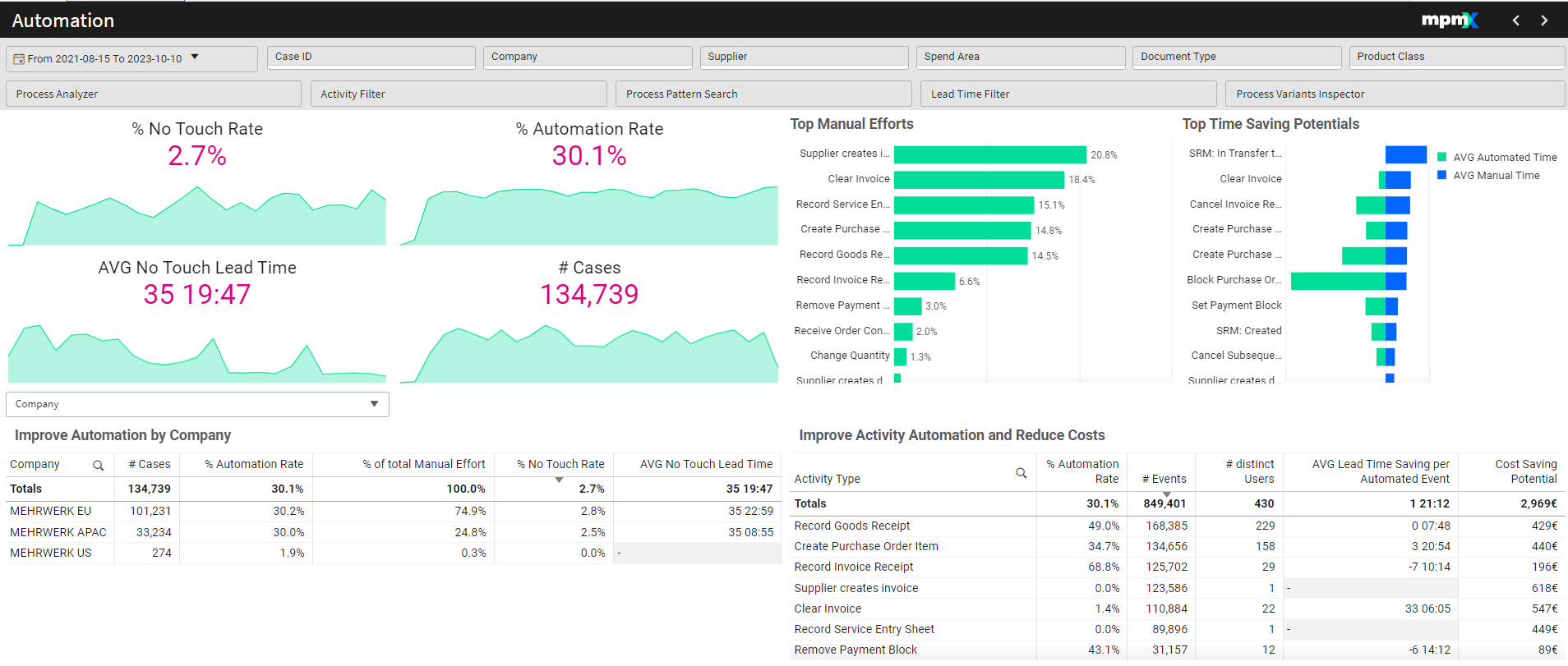

Automation

The Automation Worksheet provides insights into automation rates, manual effort reduction, and time-saving potentials in process execution. By analyzing key metrics like No Touch Rate, Automation Rate, and Time Lost by Rework, users can identify areas for improvement. Interactive charts highlight manual-intensive activities and those with the highest time-saving potential through automation. Tables offer deeper analysis by dimensions (e.g. Supplier, Product Class), enabling targeted process optimization.

Type: Dashboard

Key Figures

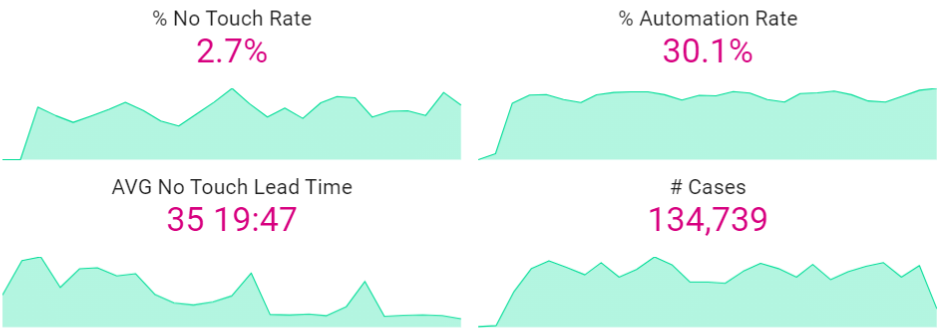

% No Touch Rate

- Represents the percentage of cases that are fully automated, meaning no manual intervention occurred at any stage.

- Ideally, a process should have a high No Touch Rate.

If this definition is too strict, remember that you can always change the definition of every PPI.

Example: In a P2P process, No Touch cases could be defined as those with automated Creation, Invoice Creation, and Payment steps.

% Automation

- Measures the percentage of automated events compared to all events.

- A high automation rate indicates a more efficient process.

AVG No Touch Lead Time

- Calculates the average lead time on cases that were fully automated.

# Cases

- Displays the total number of cases processed at the current automation level.

- Higher automation can lead to:

- More cases handled with the same resources.

- Cost savings by reducing resource requirements.

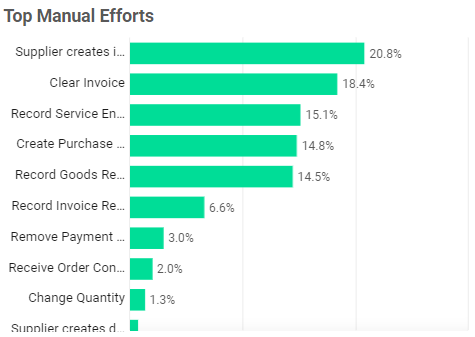

Top Manual Efforts | Bar Chart

- Displays activities requiring the most manual effort.

- Automating these activities can significantly improve efficiency.

- Selecting an item in the chart filters the KPIs and tables accordingly.

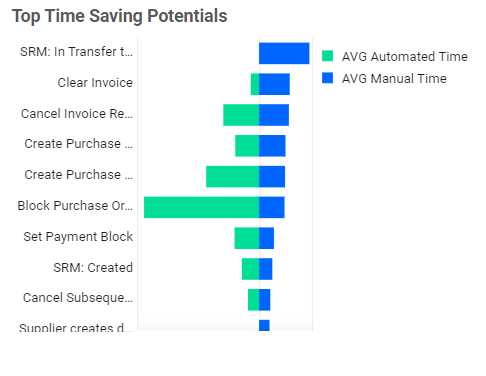

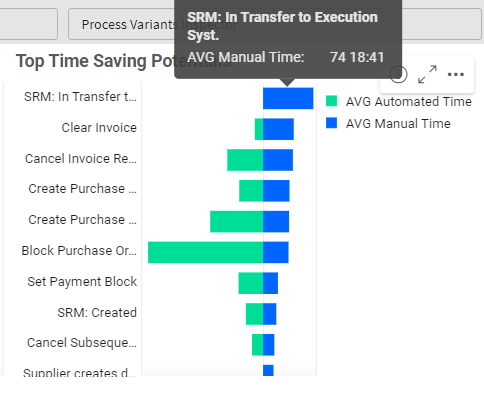

Top Time Saving Potentials | Bar Chart

- Shows activities and their frequency of manual vs. automated completion.

- Hover over an activity to view:

- Total manual time.

- Average lead time savings by automating that step (across all variants that include it).

- Selecting an activity updates the KPIs and tables to reflect its impact.

When hovering over the activity a popup will appear, showing the total manual time and the average lead time saving (across all variants that include it) by fully automating that event.

Sometimes an activity which adds a lot of lead time only affects a small number of cases and so may not have as big of an impact overall as compared to an activity with a medium lead time saving which affects a large majority of cases.

Consider prioritizing activities that affect a large number of cases for maximum impact.

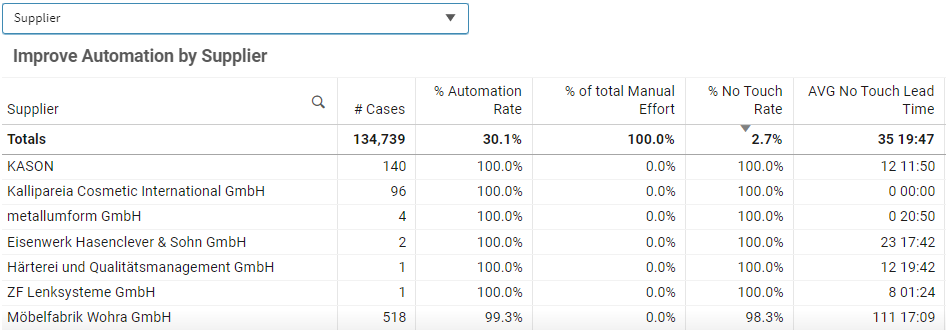

Improve Automation by (Dimension) Table

- Dropdown Selection – Analyze automation by dimensions (e.g. Supplier).

- Sorting & Filtering:

- Sort or filter by clicking or hovering over the column header you want to sort or filter.

- Identify for example Suppliers with the highest manual effort or lowest automation rates.

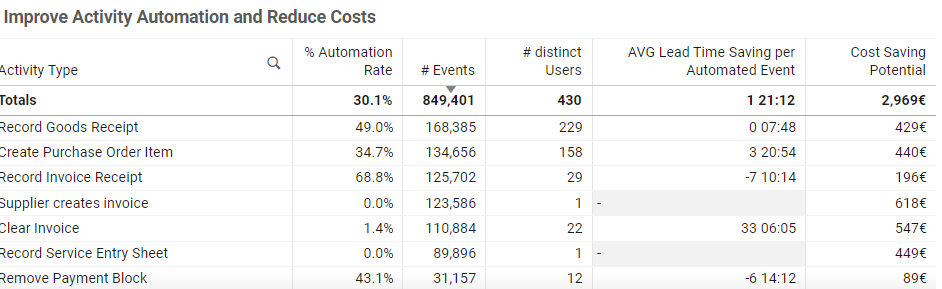

Improve Activity Automation and Reduce Costs Table

- Displays detailed information about specific activities.

- Cost Saving Potential is calculated using:

- Number of events × Duration per event × Automation potential × Cost per minute.

- This is a standard formula but can be customized based on specific needs.

Click here for more information on how to Create a Cost Calculator.